Qingdao Nanchen Q37 Series Hook-Type Shot Blasting Machines: Multi-Model Adaptability, The High-Efficiency Choice for Casting Surface Treatment

In the surface treatment processes of industries such as casting, forging, and steel structure machining, shot blasting machines serve as core equipment for achieving workpiece derusting, descaling, and surface strengthening. As the manufacturing industry continues to raise requirements for processing efficiency, adaptability, and environmental friendliness, traditional single-model shot blasting equipment can no longer meet the treatment needs of workpieces with varying specifications. The Q37 Series Hook-Type Shot Blasting Machines launched by Qingdao Nanchen Foundry Machinery Co., Ltd. have become the preferred equipment for enterprises of all scales, thanks to their gradient multi-model layout, precise technical parameter design, and eco-friendly energy-saving configurations. They provide customized solutions for the surface cleaning and strengthening of various workpieces including steel structural components, castings, and aluminum alloy parts.

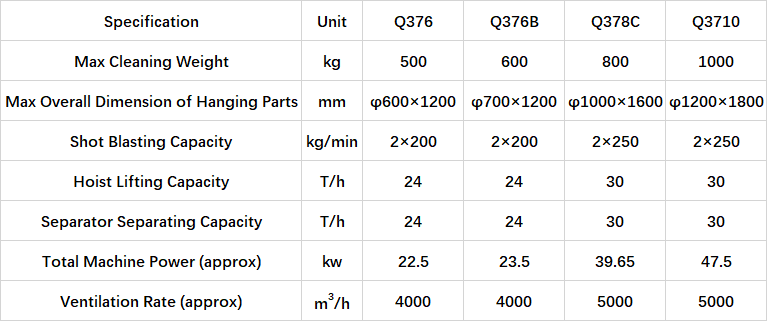

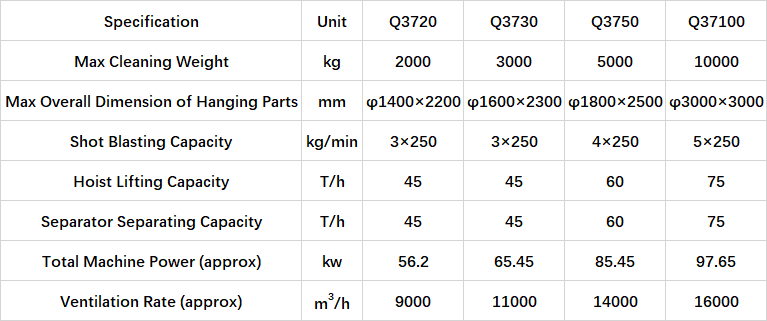

The current casting and machining industry is characterized by the diversification of workpiece specifications: small and medium-sized casting enterprises need to efficiently process standard parts within 500kg, large heavy industry enterprises are required to finish surface cleaning of 10-ton heavy-duty components, while special-shaped and non-standard parts of different sizes impose stringent requirements on the hanging size and load-bearing capacity of equipment. Meanwhile, environmental protection policies' restrictions on dust emissions and energy consumption, coupled with enterprises' control over production efficiency and operational costs, demand that shot blasting equipment must balance adaptability, high efficiency, and economic viability. Addressing these market pain points, Qingdao Nanchen's Q37 Series has built a full product matrix ranging from Q376 to Q37100, covering a cleaning weight range of 500kg to 10,000kg to match the production needs of different enterprises. Its core advantages are reflected in three key dimensions:

1. Multi-Model Matrix, Full-Scenario Coverage with No Blind Spots

The cleaning weight of the series models increases in a stepped manner from 500kg (Q376) to 10,000kg (Q37100), and the maximum hanging workpiece dimensions extend from φ600×1200mm to φ3000×3000mm. This enables the machines to adapt to the treatment of small auto parts castings, medium-sized steel structural components, and heavy-duty components such as wind power flanges respectively. For instance, the Q376 is suitable for batch cleaning of small aluminum alloy parts in hardware casting enterprises, while the Q37100 meets the surface strengthening needs of large steel components in heavy industry enterprises. Enterprises can select machines based on their actual needs according to their production capacity and workpiece specifications, avoiding resource waste.

2. Precise Parameter Design, Dual Optimization of Cleaning Efficiency and Effect

The shot blasting capacity, lifting capacity, separating capacity, and processing capability of each model are precisely matched: the Q376, with a 2×200kg/min shot blasting capacity paired with a 24T/h lifting/separating capacity, ensures high-efficiency cleaning of small castings; the Q37100, equipped with a 5×250kg/min shot blasting capacity and 75T/h lifting/separating capacity, can achieve 360° dead-angle-free derusting of 10-ton heavy-duty parts, with cleanliness stably meeting the Sa3 standard. Meanwhile, the equipment adopts high-chromium cast iron shot blaster blades and manganese steel guard plates, which double the wear resistance and achieve a shot utilization rate of 98%, significantly reducing consumable loss.

3. Eco-Friendly & Energy-Saving Configurations, Balancing Compliance and Cost Reduction

The total power of the series equipment is rationally distributed from 22.5kW to 97.65kW, which is directly proportional to the processing capacity, avoiding energy waste caused by "overcapacity operation". The ventilation volume is designed ranging from 4000m³/h to 16000m³/h to meet the dust removal needs of different models. Combined with Qingdao Nanchen's independently developed high-efficiency dust removal structure, the dust emission is far lower than the national standard, which not only meets environmental protection requirements but also reduces fan energy consumption. In addition, the high-chromium cast iron shot blaster blades and manganese steel guard plates feature excellent wear resistance, resulting in a long spare parts replacement cycle and further lowering the enterprise's operation and maintenance costs.

In the tide of high-quality development in the manufacturing industry, the upgrading and iteration of surface treatment technology are the key for enterprises to enhance their core competitiveness. Qingdao Nanchen Foundry Machinery Co., Ltd. will always be market demand-oriented and technology innovation-driven. With its intelligent and eco-friendly product advantages, full-scenario solutions, and rich practical experience, it will provide efficient and reliable surface treatment support for enterprises in various industries.