Technological Breakthroughs and Industry Applications of Qingdao Nanchen ZD Series Hydraulic Multi-contact Molding Machines

Amid the wave of intelligent and green transformation sweeping the foundry industry, clay sand casting— a traditional core process— has seen its equipment upgrading become the key for enterprises to cut costs and boost efficiency. Founded in 2003, Qingdao Nanchen Foundry Machinery Co., Ltd. has been deeply engaged in the R&D of foundry machinery for over two decades. Evolving from an initial technical research institute into a professional manufacturer integrating design, production, and service, the company has launched the ZD Series Hydraulic Multi-contact Molding Machines. With their precise technical design and strong adaptability, these machines have emerged as the core equipment for clay sand molding of medium and large-sized castings. While optimizing process efficiency, they also exemplify the path of innovative upgrading for traditional foundry equipment.

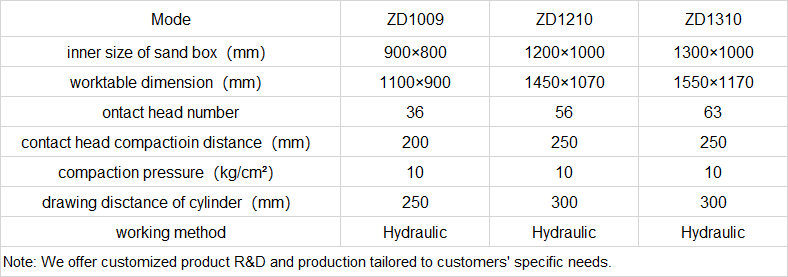

From a technical perspective, the core advantages of the ZD Series Hydraulic Multi-contact Molding Machines lie in the precision and efficiency of sand mold compaction. Tailored to the process characteristics of clay sand molding, the equipment adopts a multi-contact independent compaction design combined with micro-vibration compaction technology. Prior to contact compaction, high-frequency and small-amplitude pre-vibration is applied, which can multiply the sand mold compaction degree. Take the ZD1009 model as an example: its internal flask dimension reaches 900×800mm, and the mechanical molding process can be completed in only 10–20 seconds, far outperforming the efficiency of traditional manual molding. The number of contacts can be flexibly configured according to flask sizes— for instance, the ZD1210 is equipped with 56 contacts and the ZD1310 with 63 contacts. This adaptability meets the production requirements of medium and large-sized castings of varying dimensions, addressing the long-standing industry pain points of "uneven sand mold compaction" and "low casting precision" associated with conventional molding machines. In addition, the hydraulic drive system delivers a maximum working pressure of 16 MPa, with a maximum contact compaction stroke of 250 mm, satisfying the production demands for high-compaction castings and ensuring superior surface finish and dimensional accuracy of the final products.

Currently, the core trend in the foundry industry is the integration of intelligent upgrading and green production. It is projected that the market size of China's high-pressure multi-contact molding automatic line will exceed RMB 5.5 billion in 2025. Surging demand for lightweight castings for new energy vehicles and rail transit components is driving equipment development toward higher precision (±0.15 mm) and faster cycle times (≤45 seconds per mold). Qingdao Nanchen’s hydraulic multi-contact molding machines can operate either as standalone units or be integrated into semi-automatic molding lines, connecting with auxiliary equipment such as mold turners, flask handling manipulators, and cooling zones. This enables an integrated workflow covering sand mold conveying, pouring, and cooling, aligning with foundry enterprises’ transformation needs of "replacing manual labor with automation". Meanwhile, the equipment utilizes Mn13 wear-resistant guard plates and high-chromium alloy contacts. Leveraging the impact resistance and wear resistance of these materials, the frequency of vulnerable parts replacement is significantly reduced, which not only minimizes equipment downtime but also cuts down solid waste generation, responding to the green foundry requirements under the "dual carbon" goals.

In practical applications, the ZD Series Hydraulic Multi-contact Molding Machines have become the mainstay equipment in industries such as automotive, agricultural machinery, and power fittings. After a certain automotive component foundry introduced the equipment, the molding efficiency of medium and large engine cylinder blocks increased by 40%, and the casting rejection rate dropped from 8% to below 3%. In the construction machinery sector, excavator counterweight castings produced by this equipment have seen a 60% reduction in internal defects due to uniform sand mold compaction. Backed by a technical service team of over 20 professionals, Qingdao Nanchen provides customers with solution-based marketing services, customizing equipment parameters according to specific production needs and conducting on-site operation training. This effectively resolves the challenges of "difficult equipment operation" and "high maintenance costs" faced by small and medium-sized foundries.

Looking ahead, as the foundry industry advances toward digitalization and flexibility, Qingdao Nanchen’s hydraulic multi-contact molding machines are being upgraded for intelligent connectivity. Plans are underway to integrate sensors and data acquisition systems, enabling real-time monitoring of equipment operating status and remote diagnostics. Against the backdrop of rising industry concentration, this equipment— with its attributes of high efficiency, precision, and strong adaptability— will continue to be the preferred choice for traditional foundry enterprises undergoing technological transformation. Guided by the philosophy of "Meticulous Design, Sincere Service", Qingdao Nanchen is committed to driving the localized upgrading of clay sand casting equipment.