Qingdao Nanchen Foundry Machinery: QGT Series Inclined Drum Shot Blasting Machines

The upgrading of materials science and workpiece quality standards has highlighted the shortcomings of traditional surface treatment equipment, which can hardly meet the new requirements of new energy vehicles, high-end equipment and other fields. Adhering to the core strategy of "Technological Iteration Drives Industry Upgrading", Qingdao Nanchen Foundry Machinery Co., Ltd. invests 8% of its annual revenue in research and development. The launched QGT Series Tilting Drum Shot Blasting Machine realizes rapid function upgrading through modular design, which is compatible with the processing requirements of new workpieces such as aluminum alloy and composite materials. Having obtained ISO9001 quality management system certification and EU CE certification, it provides strong support for global manufacturing industry to cope with technological changes.

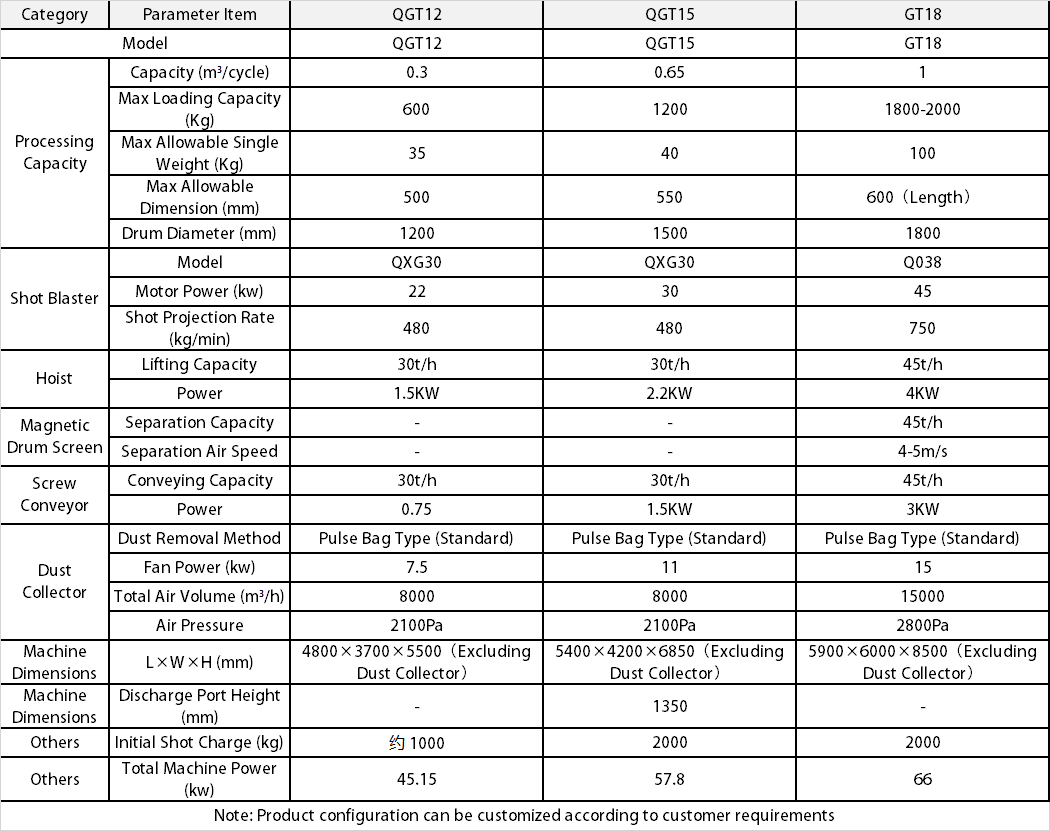

The Tilting Drum Shot Blasting Machine of Qingdao Nanchen adopts a unique tilting drum structure design, combined with a high-efficiency shot blasting system,achieving dual breakthroughs in surface treatment efficiency and quality. At present, the company's main products cover three models: QGT12, QGT15 and GT18, forming a complete product matrix to meet the needs of enterprises of different scales.

In terms of core parameters, the three models demonstrate remarkable performance advantages. In terms of processing capacity, the volume ranges from 0.3m³ per batch to 1m³ per batch, and the maximum loading capacity covers 600kg to 2000kg. Among them, the GT18 model can process large workpieces with a single weight of 100kg and a length of 600mm, solving the industry pain point of "difficult processing of large workpieces" faced by traditional equipment. The shot blasting system adopts customized design. QGT12 and QGT15 are equipped with QXG30 shot blasters with a steel shot projection capacity of 480kg per minute, while GT18 is upgraded to Q038 shot blasters with the projection capacity increased to 750kg per minute. Combined with 22-45kW motors, the shot blasting intensity can be precisely adjusted according to the workpiece material.

Environmental performance is the current focus of the industry. This series of equipment is standard-equipped with a box-type pulse bag dust collector, with a maximum total air volume of 15000m³ per hour, wind pressure of 2800Pa, and dust removal efficiency of over 99.5%, which is far lower than the national emission standard of 10mg/m³, perfectly meeting the stringent environmental requirements. Meanwhile, the equipment adopts an integrated design of magnetic drum screening and screw conveying, with a maximum lifting capacity of 45t/h, which effectively reduces shot loss and saves more than 30% of consumable costs compared with traditional equipment.

The global manufacturing industry is currently facing three core challenges: rising labor costs, increasing environmental pressure, and higher product quality requirements. Qingdao Nanchen has specially developed an intelligent control system, which realizes three major functions: real-time monitoring of equipment operation status, automatic fault diagnosis, and statistical analysis of production data. Operated via a PLC touch screen, workers can take up their posts after simple training, and a single worker can operate 2-3 sets of equipment at the same time, greatly reducing labor costs.

The equipment has a high degree of customization capability to meet the needs of different industries. In the auto parts industry, the QGT15 model, with a maximum workpiece size of 550mm and a loading capacity of 1200kg, has become an ideal choice for batch processing of wheel hubs and gearbox housings. In the construction machinery field, the GT18 model, with a maximum single-piece processing capacity of 100kg, can easily handle the surface derusting of large structural parts. The QGT12 model, with its compact overall dimensions, meets the site requirements of small and medium-sized foundry enterprises.

Driven by both Industry 4.0 and the "dual carbon" goals, Qingdao Nanchen continues to increase R&D investment, focusing on three major directions: equipment energy-saving transformation, intelligent operation and maintenance upgrading, and customized service deepening. It continuously optimizes the energy consumption performance and operational convenience of existing products, and at the same time, develops more targeted surface treatment solutions for the special needs of high-end manufacturing fields such as new energy and aerospace. The company has also established a global after-sales service network, providing 24-hour technical support and equipment maintenance to solve the worries of customers at home and abroad. As an export benchmark in China's shot blasting machine industry, Qingdao Nanchen Foundry Machinery Co., Ltd. has always adhered to the philosophy of "Technological Innovation, Quality-Oriented". By continuously optimizing product performance, it helps global customers improve production efficiency, reduce costs and achieve sustainable development. In the critical period of global manufacturing recovery, the QGT Series Tilting Drum Shot Blasting Machine is emerging as an important force driving the transformation and upgrading of the industry.