Qingdao Nanchen ZH Series Horizontal Parting Core Shooter - The Preferred Equipment for Foundry Core Making

Amid the 2025 global trend of the foundry industry shifting toward high precision and low-carbonization, the ZH600/750/870 Horizontal Parting Core Shooters launched by Qingdao Nanchen Foundry Machinery Co., Ltd. are resolving pain points such as difficult molding of thin-walled sand cores, poor multi-process compatibility and high costs for domestic and overseas enterprises through technological innovation, emerging as a cost-effective solution for high-end core making processes.

Currently, foundries around the world often encounter issues including uneven sand core density and poor coordination of multi-point sand shooting during the production of thin-walled sand cores for automotive engine blocks and pump valves. The core advantages of the ZH Series lie in its integrated design combining vertical horizontal parting with top-surface sand shooting:

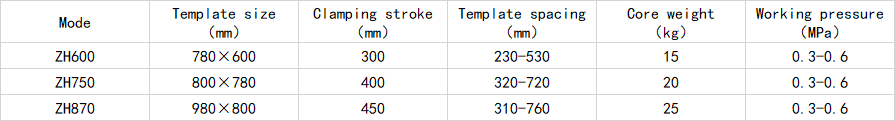

1.Wide Parameter Coverage:With mold plate dimensions ranging from 780×600mm (ZH600) to 980×800mm (ZH870), a mold clamping stroke of 300-450mm and a maximum sand core weight capacity of 25kg, it meets the molding requirements of large-area thin-walled sand cores (thickness ≤5mm).

2. High Process Precision:The sand shooting pressure is stably maintained at 0.3-0.6MPa. Combined with the multi-point sand shooting layout, the deviation of sand core density uniformity is ≤±5%, which is better than the industry average of ±8%.

3. Multi-Process Compatibility:Switching between hot box and cold box processes can be achieved simply by replacing the blowing head and core ejection plate, eliminating the need for additional modifications and significantly reducing production line transformation costs.

4.Low-Carbon Compatibility:Precision sand shooting control ensures a 92% utilization rate of precoated sand. Carbon emissions per ton of sand cores are reduced by 120kgCO₂e compared with traditional equipment, complying with the EU Industrial Carbon Emission Limits standards.

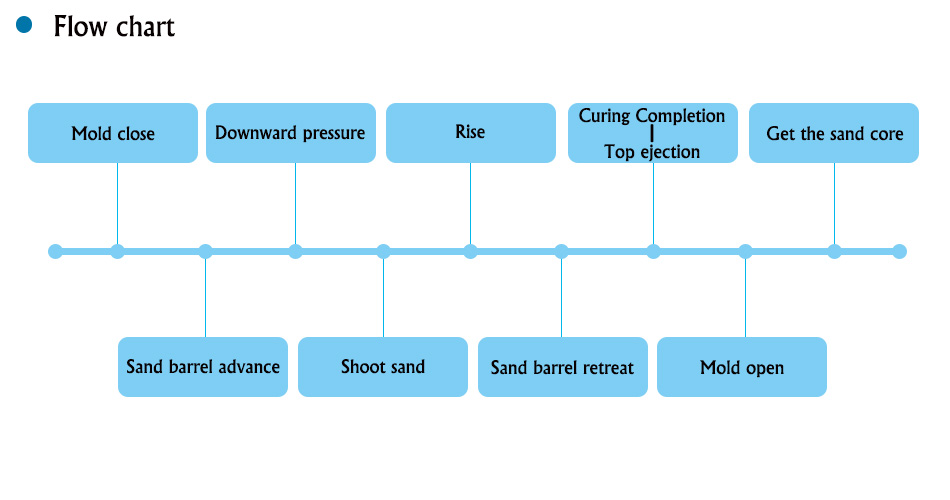

The ZH750 model has demonstrated outstanding value in the production of turbine housing sand cores at a domestic auto parts manufacturer: The scrap rate of thin-walled turbine housing sand cores (1.2㎡ area, 4mm thickness) produced by the factory’s original equipment reached 8%, while the ZH750 reduced the scrap rate to 1.5% through simultaneous filling via 12 sand shooting points. Its fully automated process (mold clamping → sand shooting → curing → mold opening → core extraction) shortened the single-core cycle time from 45 seconds to 32 seconds, increasing daily production capacity by 40%. In the pump and valve industry, the ZH870, with its 980×800mm mold plate size, achieves one-piece molding of complex internal cavity sand cores for large valve bodies, replacing the traditional multi-core splicing process and improving casting assembly precision by 0.3mm grade.

In 2025, zero-carbon core making and cost reduction with efficiency improvement are core priorities for the global foundry industry, and the ZH Series meets both requirements simultaneously:

1. Low-Carbon Compatibility:Its high sand utilization rate and energy-efficient design perfectly align with the carbon emission reduction targets of domestic and overseas foundry enterprises, enabling direct integration into factory low-carbon production management systems.

2. Cost Advantage:As domestically manufactured equipment, its procurement cost is 30%-40% lower than that of imported models, with delivery lead time shortened by more than 50%. In addition, core components are locally sourced, reducing subsequent maintenance costs by approximately 45% compared with imported equipment.

Backed by over 20 years of experience in foundry equipment manufacturing, Qingdao Nanchen has made the ZH Series a popular choice in the market with its combined advantages of structural innovation, multi-process compatibility and low-carbon cost reduction. This equipment not only meets the precision requirements of high-end core making, but also adapts to the green transformation and cost control needs of the global foundry industry, serving as a practical option for domestic and overseas enterprises upgrading their core making processes.