Qingdao Nanchen ZH-L Series Cold Box Horizontal Parting Core Shooter

As one of the most competitive manufacturers of complete sets of foundry machinery and equipment in China, Qingdao Nanchen Foundry Machinery Co., Ltd. has launched the ZH-L Series Cold Box Horizontal Parting Core Shooter. This product line precisely meets the core demands of "large-scale, high-precision, and high-safety" in the global foundry industry, and provides professional core shooting solutions for the efficient production of high-end and complex sand cores in sectors such as automotive, wind power, and rail transit.

Currently, the demand for "large and complex sand cores" is continuously rising in fields including automotive engine blocks/cylinder heads, wind turbine hubs, and rail transit bogies. However, the production of large sand cores is commonly plagued by issues such as the need for operators to access the interior of equipment for core removal and mold changing, leading to low efficiency and high safety risks. Traditional core shooters also suffer from poor sand shooting uniformity and high core box deformation rates, which directly compromise casting precision. Additionally, the emission of core-making exhaust gas and enclosed operating spaces fail to meet the safety and environmental standards of modern industry. The ZH-L Series is a specialized core shooting equipment developed to address these key industry challenges. Covering three main models (ZH850L, ZH1100L, ZH1412L), it supports the efficient production of sand cores ranging from 30kg to 80kg, comprehensively resolving the production pain points in the foundry industry. To achieve these goals, the ZH-L Series has undergone targeted innovations in parameter configuration and structural design:

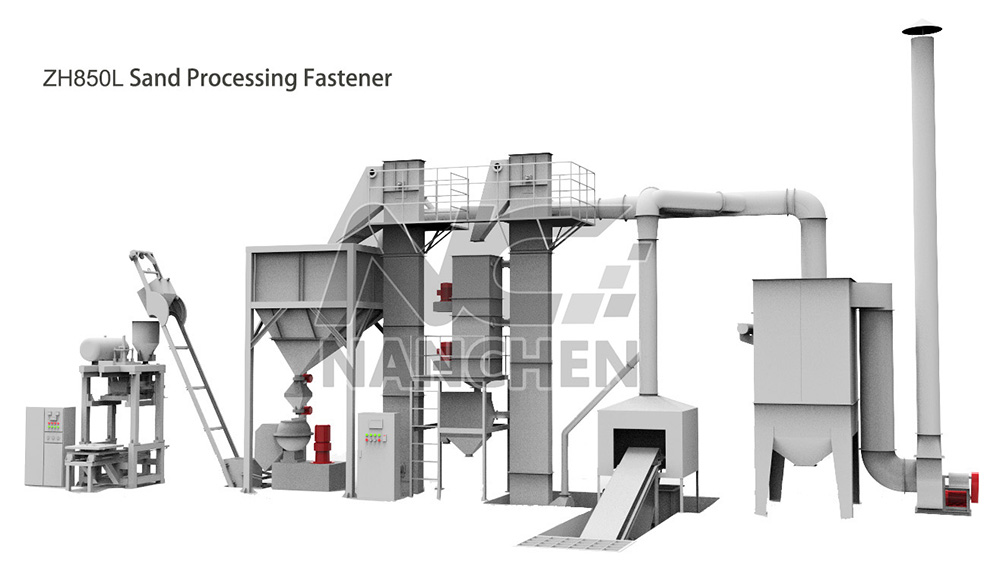

1. Model Parameter Configuration

As the entry-level model in the series, the ZH850L Core Shooter features a mold plate size of 850×850mm and a sand shooting range of 600×580mm, suitable for producing small-to-medium-sized complex sand cores weighing up to 30kg. Its 400mm mold clamping stroke balances operational flexibility and molding stability, making it ideal for the mass production of sand cores for small automotive engine components, pumps, and valves.

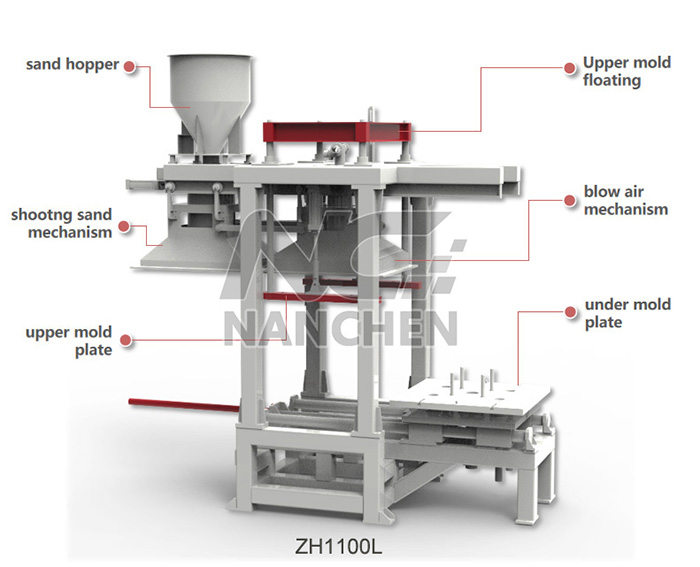

The ZH1100L, a mid-range model, boasts upgraded mold plate size and sand shooting range, capable of handling 40kg sand cores. It is well-suited for manufacturing mid-end complex sand cores such as those for automotive engine cylinder heads and intake manifolds. Retaining the 400mm mold clamping stroke, it adopts a floating upper mold structure design that effectively controls core box deformation even when producing large-sized sand cores, making it a core model that balances precision and production capacity.

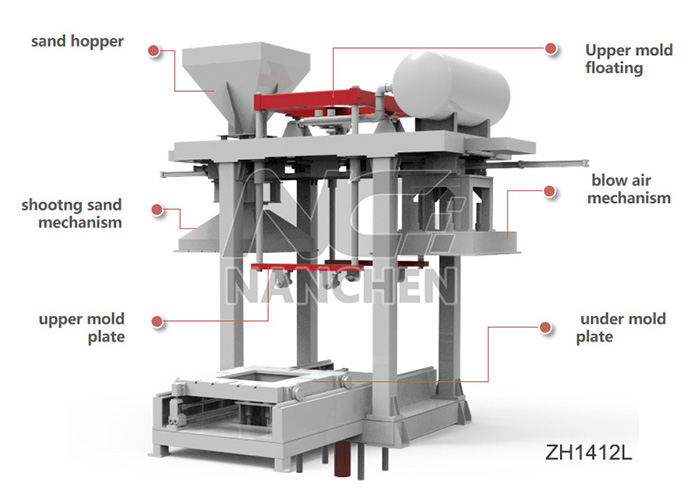

The ZH1412L is a large-scale cold box horizontal parting core shooter engineered for heavy-duty sand core requirements. With an extra-large mold plate size of 1200×1400mm and a sand shooting range of 1100×1250mm, it enables stable production of 80kg-class sand cores. Its extended 600mm mold clamping stroke meets the molding requirements of complex cavity sand cores for wind turbine hubs and rail transit bogies.

2. Model Structural Design

The ZH-L Series Core Shooter adopts a hydraulically retractable lower mold plate design, allowing operators to safely and efficiently perform core removal and mold changing in an open space, thus completely resolving the operational challenges associated with large sand core shooters.

The ZH1100L and ZH1412L models are equipped with a floating upper mold clamping structure, which greatly enhances equipment operational stability and effectively reduces core box deformation rates.

A rigid steel pipe connection air blowing mechanism replaces traditional hoses, significantly improving air pressure stability and sealing performance, and increasing sand core curing uniformity by 20%.Additionally, the series comes with modular safety configurations, which can be customized with safety fences, light curtains, and a sealed cover coupled with an air extraction and exhaust system as needed. This setup effectively isolates core-making exhaust gas and fully complies with EU industrial safety standards, comprehensively addressing the issues of operational safety, molding precision, and environmental compliance faced by traditional core shooters.

As a leading enterprise in China's complete foundry machinery and equipment industry, Qingdao Nanchen has always taken technological innovation as its core driving force. It strictly adheres to international industrial standards in product R&D and manufacturing. Its equipment has not only obtained multiple quality system certifications but also earned an excellent reputation through practical applications in numerous countries and regions worldwide. Looking ahead, Qingdao Nanchen will continuously upgrade the core technologies of the ZH-L Series Cold Box Horizontal Parting Core Shooter and expand the range of models suitable for diverse application scenarios. Meanwhile, relying on its comprehensive global service network, the company will provide domestic and international customers with full-cycle support covering equipment selection, installation and commissioning, as well as after-sales maintenance.