Qingdao Nanchen GS Series High-Efficiency Rotor Sand Mixer - Customer Q&A

Q: What are the common problems in the sand mixing process of the current foundry industry?

A: There are 4 core problems in the current sand mixing process:

1. Poor sand mixing uniformity (industry average error ≥ 5%), leading to a casting defect rate as high as 6%-8%;

2. High energy consumption, which is difficult to meet low-carbon requirements such as the EU CBAM and China's "Dual Carbon" goals;

3. Mismatch between production capacity and the rhythm of automated foundry production lines, slowing down the overall process efficiency;

4. Rapid wear of wearing parts and frequent maintenance increase costs. The GS Series High-Efficiency Rotor Sand Mixer is a special equipment designed to solve these problems.

Q: What technology does the GS Series High-Efficiency Rotor Sand Mixer rely on to solve these sand mixing problems?

A: The core is the "double disc + high-speed rotor" composite drive technology: the low-speed double discs drive the overall circulation of sand materials, and the high-speed rotor exerts strong shearing, impact and turning forces on the sand materials to achieve "macro coverage + micro uniform mixing". Finally, the sand mixing uniformity error is ≤2.5%, and the casting defect rate is reduced to less than 3% from the source, greatly improving the processing quality of the sand mixer.

Q: What is the energy consumption performance of the GS Series? Can it meet international carbon compliance requirements?

A: The GS Series has leading energy consumption performance in the industry: its energy consumption per ton of sand processed is as low as 1.5Kw·h/t, which is 30% lower than that of traditional rotor sand mixers under the same production capacity. In terms of domestic compliance, it not only aligns with the energy consumption control direction of China's "Dual Carbon" goals but also meets national standards such as the "Energy Consumption Quota for Unit Products in the Foundry Industry". In terms of international compliance, its low energy consumption performance is compatible with the carbon emission accounting rules of the EU Carbon Border Adjustment Mechanism (CBAM) and complies with environmental protection regulations of the North American foundry industry, helping enterprises avoid carbon tariff risks in the international market and smoothly enter the international casting market.

Q: How to select the model of the GS Series for foundry production lines of different scales?

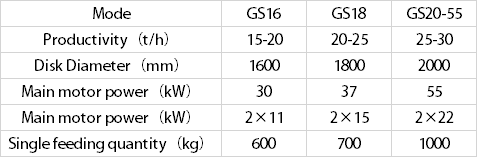

A: The GS Series High-Efficiency Rotor Sand Mixer covers the entire production capacity range and is accurately adapted to different production lines:

1. GS16 for small and medium-sized production lines: production capacity 15-20t/h, disc diameter 1600mm, main motor power 30kW;

2. GS18 for medium-sized production lines: production capacity 20-25t/h, disc diameter 1800mm, main motor power 37kW;

3. GS20-55 for large-scale continuous production lines: production capacity 25-30t/h, disc diameter 2000mm, main motor power 55kW.

Q: Is there any case support for the actual production effect of the GS Series?

A: After a domestic casting factory switched to the GS Series, its production capacity increased from 20t/h to 30t/h, the casting defect rate decreased from 7.5% to 2.8%, and the annual cost saving exceeded 200,000 RMB.

Q: Is the long-term operation and maintenance cost of the GS Series High-Efficiency Rotor Sand Mixer high?

A: No, it is not high. The service life of its wearing parts is extended by 20%, the maintenance interval is extended from the industry's conventional 1 month to 2-3 months, the equipment downtime is reduced by 60%, and the comprehensive operation and maintenance cost is reduced by 15%.