Technical and Application Instructions for Qingdao Nanchen S25 Series Fixed Double-Arm Sand Mixer

Against the backdrop of the global foundry industry's transformation towards green, intelligent, and high-efficiency production, resin sand molding, as the current mainstream process, is still plagued by issues such as poor sand mixing uniformity, high hot sand loss, and difficult equipment maintenance, which restrict the capacity upgrading of small and medium-sized foundries. The S25 Series Fixed Double-Arm Sand Mixer developed by Qingdao Nanchen Foundry Machinery Co., Ltd. is a dedicated continuous mixing device designed for resin self-hardening sand preparation, providing global users with a solution that combines technical adaptability and cost-effectiveness.

The S25 Series Fixed Double-Arm Sand Mixer is a sand preparation equipment that integrates the features of a high-efficiency sand mixer and an environmentally friendly sand mixer, with its core advantages reflected in the following three aspects:

1. Intelligent Control and Precise Feeding

The equipment is equipped with a PLC programmable electrical control system, supporting one-key start-stop at the front end and LCD display of working parameters. It enables real-time adjustment of sand mixing speed and material ratio, reducing manual adjustment errors. Its continuous pneumatic liquid supply system can precisely control the flow rate of liquid additives such as resin and curing agent, cutting hot sand and tail sand loss by more than 30% and achieving a sand mixing uniformity of ±0.5%, which prevents casting scrap caused by uneven sand mold strength.

2.Scenario-Based Adaptation of Core Parameters

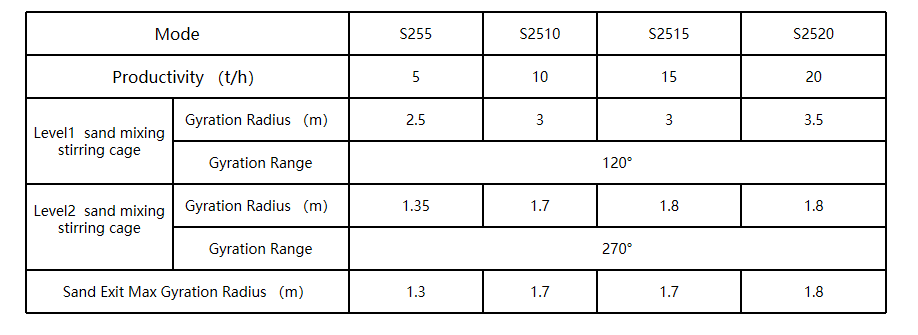

The S25 Series includes four models: S255, S2510, S2515, and S2520, with parameter gradients fully matching the needs of different scales and scenarios. Ranging from the S255 with a capacity of 5t/h (suitable for small-batch precision casting production lines) to the S2520 with 20t/h (suitable for large-scale auto chassis part production lines), it not only avoids "cost waste caused by overcapacity" but also solves the problem of "delayed delivery due to insufficient capacity". The primary mixing cage has a swing radius of 2.5-3.5m and a swing range of 120°, covering large sand boxes with a diameter of 5-7m. The secondary mixing cage features a swing radius of 1.35-1.8m and a swing range of 270°, enabling flexible switching between 3 adjacent station sand boxes without moving the equipment, thus improving workshop space utilization by 40%. The sand outlet height gradient of 1.3-1.8m can directly meet the feeding requirements of sand boxes ranging from small manual ones (1.2m high) to large automated ones (2.0m high), eliminating the need for additional lifting devices and reducing production line transformation costs.

3.High Reliability and Easy Maintainability

The equipment adopts high-flow wear-resistant diaphragm pumps, high-specification electromagnetic directional valves, and branded electrical components to ensure the stability of continuous operation. Its full-open structure allows blade cleaning, adjustment, and replacement without disassembling the entire machine, cutting maintenance time to 1/4 of that of traditional equipment, which is suitable for the actual needs of small and medium-sized foundries at home and abroad with "limited skilled worker resources".

A domestic auto parts foundry using a single-arm sand mixer experienced a casting surface defect rate of 8% due to uneven sand mixing and had to shut down the equipment for 2 hours daily for cleaning. After introducing the S2515 model (with a productivity of 15t/h, primary swing radius of 3m, and sand outlet height of 1.7m), the sand mixing uniformity was improved to ±0.4%, and the casting defect rate was reduced to 1.2%. Hot sand loss was decreased by 28%, and the average monthly effective operation time of the equipment was increased from 200 hours to 280 hours. The 270° swing range of the secondary mixing cage is compatible with 3 adjacent sand boxes, eliminating the need for frequent equipment position adjustments and improving workshop operation efficiency by 35%. Meanwhile, the intelligent liquid supply system reduced the cost of resin consumables by 12%, meeting the foundry's dual demands of "environmental protection + cost reduction".

Currently, foundry enterprises at home and abroad are facing pressures such as high labor costs and strict environmental protection standards, with some enterprises suffering from low equipment precision and insufficient capacity. The intelligent control of the S25 Series reduces labor dependence, and its continuous pneumatic liquid supply system complies with EU environmental protection standards. The equipment procurement cost is only 60% of that of similar products, and Qingdao Nanchen provides global warranty and 24-hour response after-sales support, solving the problem of inconvenient equipment maintenance for users at home and abroad.As the core product of Qingdao Nanchen, the S25 Series Fixed Double-Arm Sand Mixer, characterized by high efficiency, precision, and easy maintenance, is emerging as the core equipment for small and medium-sized foundries worldwide in their transformation from "traditional molding" to "modernized production". From auto parts to engineering machinery castings, from precision hardware to large-scale shells, this equipment is leveraging the strength of Made-in-China Intelligence to redefine the efficiency and quality of resin sand mixing.