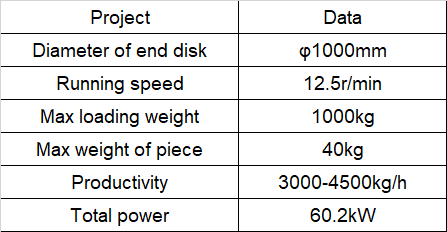

Qingdao Nanchen QR3220 Crawler-type Automatic Loading Shot Blasting Machine

The QR3220 is a crawler-type shot blasting machine integrating automation, intelligence and environmental-friendliness, specially designed for the surface treatment of small and medium-sized castings, forgings and mechanical parts. This shot blasting machine is suitable for workpieces with a single weight ≤ 300kg and a diameter ≤ 600mm, capable of realizing scale removal, derusting and surface strengthening functions. The cleaning grade stably reaches Sa2.5-Sa3, meeting the requirements of high-end pre-coating treatment and improvement of parts fatigue strength. With the core advantages of "low energy consumption, low emission and high automation", it is applicable to fields such as automotive manufacturing, engineering machinery and new energy equipment. It not only supports independent operation of a single machine, but also can be integrated into digital workshops, serving as a supporting shot blasting equipment for the intelligent upgrading of foundry enterprises.

The QR3220 Crawler-type Automatic Loading Shot Blasting Machine is equipped with an automatic loading and continuous operation system, realizing unmanned operation throughout the whole process of workpiece conveying, cleaning and discharging, and solving the problems of "labor shortage and high labor cost" in the foundry industry. It is furnished with a high-power and high-efficiency shot blaster, with a single machine shot blasting capacity of 3000-4500kg/h. The cleaning efficiency is 20% higher than that of traditional shot blasting machines, far exceeding the industry average. Adopting a three-stage shot-sand separation system with a separation efficiency of up to 99%, it ensures uniform shot spraying, and the workpiece surface roughness is controlled within Ra1.6-Ra6.3μm. The high manganese steel crawler is hardened, featuring excellent wear resistance and impact resistance, and is suitable for workpieces of various materials such as cast iron, cast steel and aluminum alloy. The annual failure rate of the equipment is less than 1%. The equipment adopts an energy-saving motor and an optimized shot recycling system, reducing the unit energy consumption by 15% compared with the industry level, and the shot recycling rate reaches more than 85%, significantly lowering the operation cost.

This shot blasting machine is widely applicable to multiple fields including automotive manufacturing, engineering machinery, new energy equipment and general machinery. It can clean small and medium-sized castings, forgings and mechanical parts such as engine blocks, wheel hubs, hydraulic components, wind power connectors, battery cases and hardware tools, meeting multiple process requirements such as scale removal, derusting, surface impurity stripping, deburring and surface strengthening. It can not only satisfy the basic cleaning standards before ordinary coating, but also meet the stringent requirements for improving the fatigue strength of precision parts. Compatible with various materials like cast iron, cast steel and aluminum alloy, it can flexibly adapt to mass production and flexible processing scenarios. It supports both independent operation of a single machine and integration into automatic production lines for linkage operation, fully meeting the differentiated production needs of different industries.

The QR3220 is equipped with a PLC touch screen control system, and operators can independently operate it after 2 days of training. The equipment adopts a modular design, with core components such as shot blasters and dust collectors detachable. The replacement cycle of wearing parts such as blades and directional sleeves reaches 400-500 hours, and it supports fast symmetrical replacement in pairs (weight error ≤ 5g). The maintenance time and cost are reduced by 30% and 20% respectively compared with the industry. In terms of safety, the equipment fully complies with international safety standards, equipped with a protective door interlock device. An emergency stop button is installed within 1 meter of the operation area, which can instantly cut off the main power supply. The operation noise is ≤ 85dB. Operators can work safely by wearing protective masks and earplugs without direct dust contact throughout the process, comprehensively ensuring personal safety and occupational health.

The QR3220 Crawler-type Automatic Loading Shot Blasting Machine responds to industry demands with technological innovation, lowers the threshold for use with convenient maintenance and safe design, and is an ideal choice for global foundry enterprises to reduce costs, improve efficiency and achieve green transformation. Relying on the transportation advantages of National Highway 204 and Shenhai Expressway, the company has established an efficient global logistics and after-sales service network, providing overseas users with one-stop services such as technical consultation, installation and commissioning, and spare parts supply. Under the development opportunity that the global shot blasting machine market scale is expected to exceed 3.5 billion US dollars, the QR3220, with its excellent performance, environmentally-friendly design and high cost performance, is becoming a reliable partner for the upgrading and transformation of global manufacturing enterprises.