Qingdao Nanchen Z94 Series Double-Station Vertical Parting Hot Box Core Shooter

The Z94 Series Double-Station Vertical Parting Hot Box Core Shooter is a dedicated piece of equipment for forming small and medium-sized sand cores. It cures sand cores via heating in the hot box, combined with a core shooting pressure of 0.3-0.6MPa, delivering an efficient and reliable integrated solution for sand core manufacturing.

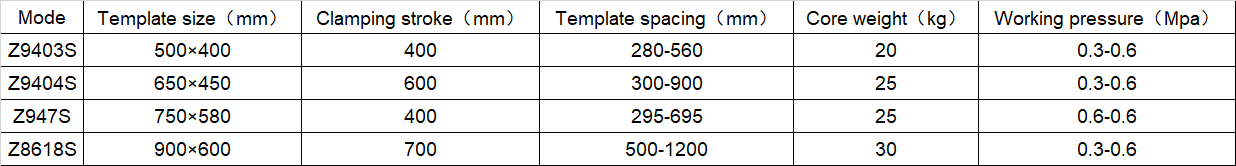

This series of core shooters includes four main models, fully catering to diverse production requirements: The mold plate size ranges from 500×400mm to 900×600mm, with a sand core load-bearing capacity of 20-30kg. This not only precisely meets the manufacturing needs of small and medium-sized sand molds but also expands the production potential of larger-spec sand cores through the large-size mold plate models. The working pressure range of 0.3-0.6MPa can be adjusted according to the material and structure of the sand core, ensuring the uniformity and compactness of different types of sand cores during molding. Among them, the Z9403S model features a 500×400mm mold plate, a 400mm clamping stroke, and a mold plate spacing of 280-560mm, suitable for lightweight sand core production; the Z8618S model, with a large 900×600mm mold plate and a 700mm long clamping stroke, meets the manufacturing requirements of larger-spec sand cores.

The equipment adopts a double-station independent layout, allowing two sets of molds to be installed simultaneously. Each station supports independent parameter setting, enabling single-station production or parallel operation of both stations without mutual interference. Addressing the pain point of cumbersome switching between multiple product types, it can quickly switch to the production of sand cores of different specifications, reducing the costs of mold replacement and parameter debugging. For the problem of low efficiency in batch production, the parallel operation of double stations increases productivity by 50%-80% compared with traditional single-station equipment. The core components of this series of hot box core shooters are low-temperature resistant and dust-proof, solving the problem of insufficient stability under harsh working conditions and ensuring stable operation in complex environments. Its precision clamping mechanism has a repeat positioning accuracy error of ≤0.1mm, effectively controlling the dimensional deviation of sand cores. Combined with stable working pressure output, the sand core rejection rate is reduced to below 3%, cutting down material waste. Meanwhile, equipped with a touch interface and featuring a compact structure, it is easy to operate and suitable for compact production layouts. It complies with international safety and environmental standards, supports customized adjustments, and adapts to the needs of different production scenarios.

This series of core shooters is mainly applied in the automotive and construction machinery sectors, for manufacturing small and medium-sized sand cores of key components such as engine blocks, hydraulic parts, and valves. It can also be extended to industries like agricultural machinery and general machinery, boasting a wide application range. Currently, the casting industry is moving towards upgrading in terms of high efficiency, precision, and environmental friendliness. The Z94 Series Double-Station Vertical Parting Hot Box Core Shooter aligns with this trend and meets customers' core demands for equipment production flexibility, operational stability, and compliance adaptability.

In terms of operation, the touch interface of the core shooter reduces the difficulty of learning and operation, with a concise parameter setting process that allows operators to get started without complex training. In terms of maintenance, the equipment has a simple structure, with key maintenance points arranged reasonably and easily accessible. Wearing parts can be replaced conveniently, reducing downtime for maintenance and operation costs. In terms of safety, this series of core shooters complies with international safety standards for casting equipment and is equipped with multiple safety protection devices, effectively preventing the risk of mechanical injury during operation. In terms of environmental protection, the emission indicators meet relevant standards, with no excessive emission of harmful gases, helping enterprises achieve green production.

Relying on a global service network, Qingdao Nanchen provides a full-cycle service covering core shooter scheme design, installation and commissioning, and remote operation and maintenance. The technical team has more than ten years of industry experience and can quickly respond to customer needs in different regions. Moreover, adjacent to the Shenhai Expressway, the company enjoys convenient land, water, and air transportation, providing efficient logistics distribution and spare parts supply guarantees for customers worldwide.