ZH-L Series Cold Box Horizontal Parting Core Shooter Selection Guide

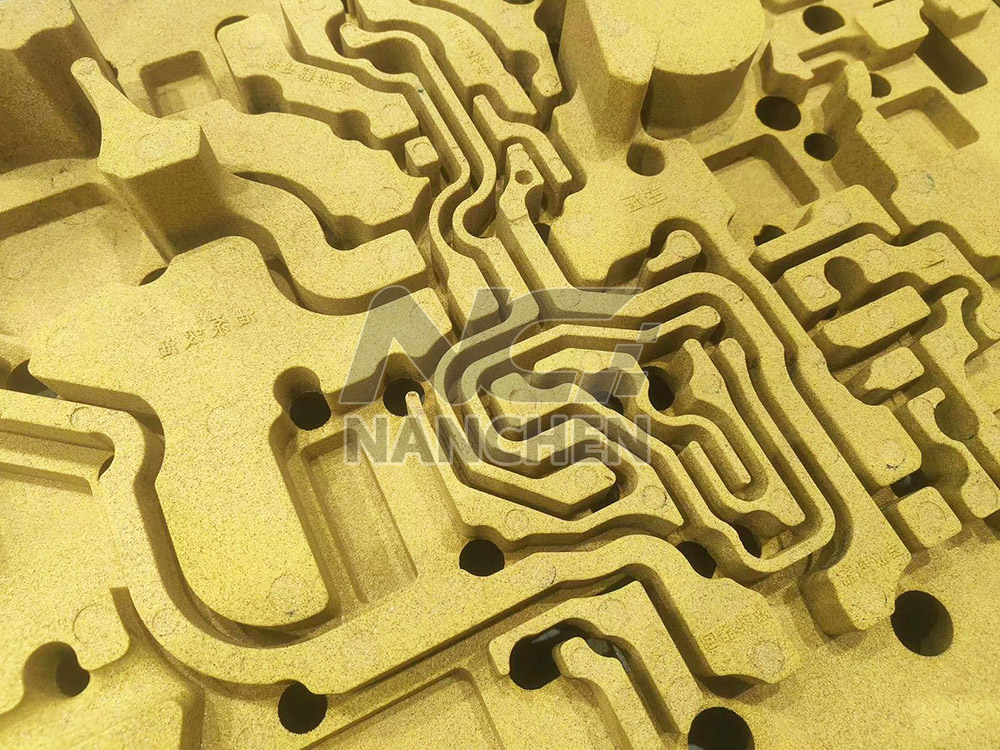

The ZH-L Series Cold Box Horizontal Parting Core Shooter is a dedicated molding equipment for large and complex sand cores. Based on mature cold box core making technology, it realizes integrated operation of sand shooting, mold clamping and sand core curing through precise hydraulic drive, perfectly meeting the molding requirements of high-demand casting sand cores in industries such as automobile manufacturing and construction machinery.

1.Product Technical Highlights

Hydraulic Drive for Precise Molding: This series adopts hydraulic drive mode, which can accurately control the pressure and stroke of key actions such as mold opening/closing and sand shooting, ensuring sand core molding precision and effectively avoiding defects like material shortage and deformation of complex sand cores. Among them, larger models adopt upper mold moving structure, further improving operational stability and reliability, and adapting to high-intensity continuous production scenarios.

Removable Structure for Efficient Mold Change: Equipped with a removable lower template design, the lower template can be directly moved out of the sand shooting station, completely solving the industry pain points of difficult core extraction and cumbersome mold change for large and complex sand cores. The mold change time is significantly shortened compared with traditional equipment, greatly improving production efficiency.

Steel Pipe Hard Connection for Stability & Reliability: The air blowing mechanism is upgraded to a steel pipe hard connection mode. Compared with traditional rubber hose connection, it has better sealing performance under high-pressure operation environment, reduces failure rate, provides stable guarantee for uniform curing of sand cores, and extends the continuous operation time of the core shooter.

2.Selection Reference Factors

Sand Core Specifications: The ZH-L Series covers three main models, with template sizes ranging from 850×850mm to 1200×1400mm and maximum sand core weight up to 30-80kg. During selection, it is necessary to focus on matching the actual size, weight and structural complexity of the sand core to ensure that the equipment workbench and sand shooting range fully cover the sand core molding requirements.

Process Requirements: This series is specially designed for cold box core making process and can accurately adapt to the sand core curing process under this technology. If there are specific requirements for gas tightness and curing efficiency in production, selection can be made based on the high-pressure adaptation characteristics of the air blowing mechanism to ensure seamless connection with the existing production process.

Production Efficiency: For high-frequency mold change or multi-variety sand core production, all models with removable lower template structure are preferred, whose efficient mold change capability can reduce non-production time; for large-scale continuous production scenarios, larger models can be focused on, and the stability of the upper mold moving structure can be used to improve the output per unit time.

3.Application Scenarios & Customized Selection Support

This series is suitable for production scenarios requiring complex internal structures or large-volume sand cores, such as automobile cylinder blocks, construction machinery valve bodies, and large hydraulic components. It can meet the core making needs of various material castings including carbon steel, ductile iron and aluminum alloy, and adapt to different production scales from small-batch customization to large-scale mass production. We also provide comprehensive customized services, and can flexibly adjust configurations such as template size and sand shooting range according to customers' sand core specifications, production processes, safety standards and environmental requirements. For accurate selection, it is recommended to provide specific sand core size, weight, structural drawings and daily output targets. We will match you with the optimal model to maximize the core making efficiency and molding precision advantages of the equipment.